Search

ADD:Building 123, Phase 3, Enterprise Base, No. 1 Lianhua Street, High-tech Industrial Development Zone, Zhengzhou, Henan, China

MOB.: +86-15517518512

MOB.: +86-15515520695

E-MAIL: admin@dais.ltd

In the stretching process, the quality of lubricant and the supply of lubricant affect the service life of the drawing die. Therefore, the lubricant is required to have a stable oil base, good oxidation resistance, excellent lubricity, cooling and cleaning properties, and always maintain the best lubrication state throughout the production process, so as to form a layer that can withstand high pressure without being damaged The thin film reduces the friction in the working area and improves the service life of the mold.

During the use process, the condition of the lubricating oil should be continuously observed.

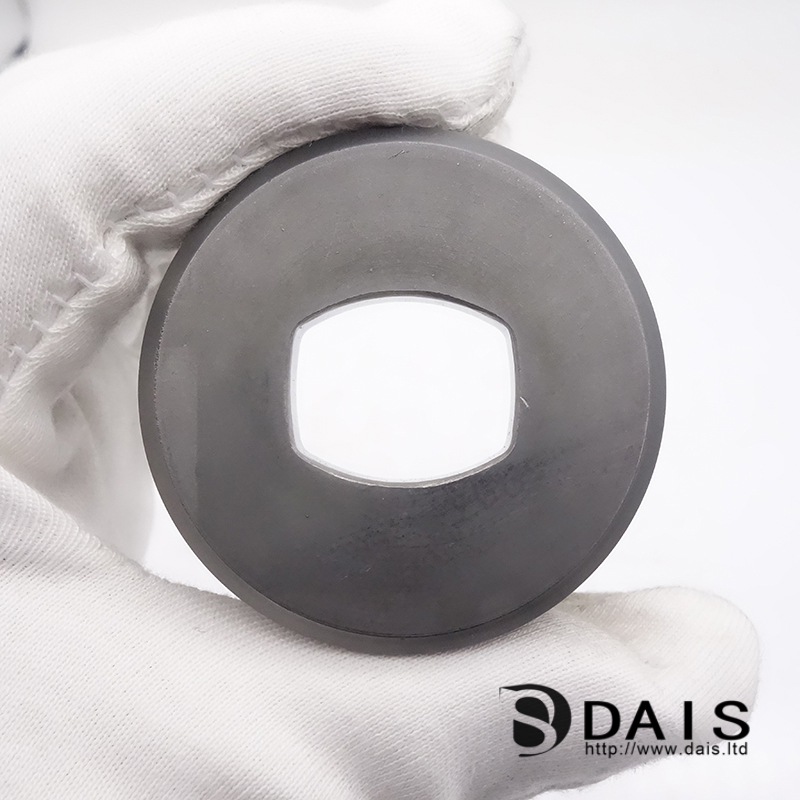

Wire drawing die

Replace or filter in time to prevent the lubricating oil from degrading due to oxidation, and to prevent the fine metal particles falling off during the drawing process from damaging the mold.