Search

ADD:Building 123, Phase 3, Enterprise Base, No. 1 Lianhua Street, High-tech Industrial Development Zone, Zhengzhou, Henan, China

MOB.: +86-15517518512

MOB.: +86-15515520695

E-MAIL: admin@dais.ltd

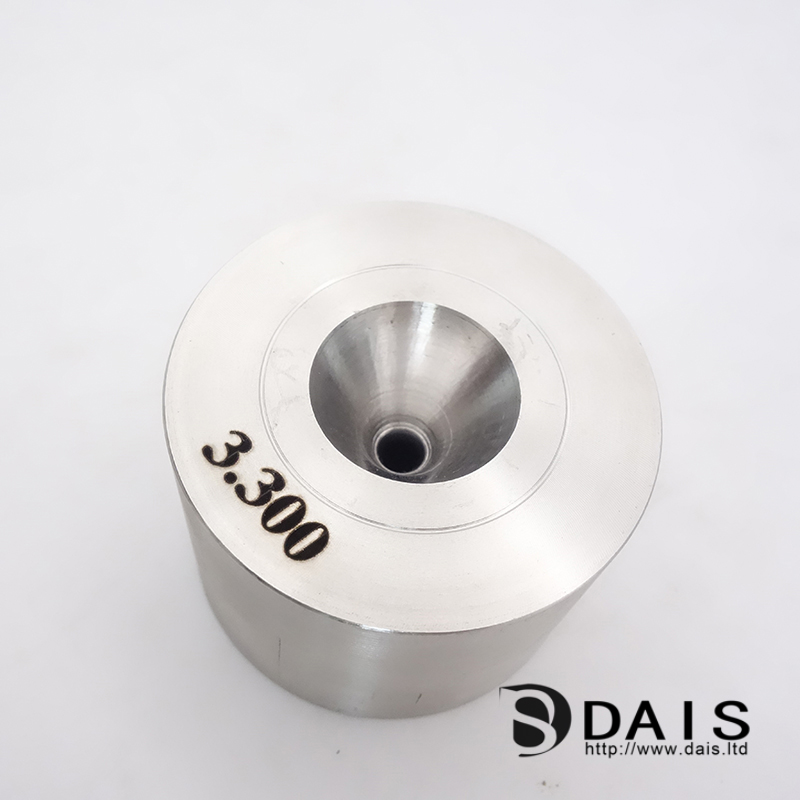

The inner hole of the drawing die is composed of a cylindrical conical surface. The cone is the compression zone for the wire (work). The cylindrical surface is the sizing area (polishing zone) of the drawing die. The diameter L corresponds to the wire ruler J. The quality of the drawing die directly dialects the shape, size, surface roughness and service life of the material wire. The wire-drawing die hole grinding process used in our country a few days ago is the needle grinding process introduced from the Soviet Union in the early 1950s. Its working principle is that the mold rotates and the needle-shaped grinding head moves or swings slightly in the grinding hole to achieve the daily processing of the mold hole. This process has low reliability and low production efficiency. The needle-shaped grinding head is designed into a cone shape to make it easy to penetrate into the mold, and at the same time, the radial force component is generated during the grinding process to improve the grinding effect. But it also brings many drawbacks. First of all, the taper of the needle grinding head makes the die hole of the processed rice also have a taper. When the taper die hole is used for drawing, only the small end of the taper die hole plays a role in sizing. The sizing area is small, so the contact area during polishing operation is small. Then due to the existence of periodic contact load or alternating stress on the micro-volume acting on the friction surface during the working process of the wire drawing die, it is very easy to make the surface or subsurface And cracks are formed. As a result, the mold hole L is severely worn, and the wire polishing quality is poor. Secondly, the needle-shaped grinding head is manufactured by work repair, and the shape of the grinding head is extremely difficult to present an ideal conical shape. Therefore, in the grinding process, because the needle grinding head is tapered, the radial component force exists, and it is almost impossible to completely balance it. The resulting eccentric force makes the suspended grinding head appear.