Search

ADD:Building 123, Phase 3, Enterprise Base, No. 1 Lianhua Street, High-tech Industrial Development Zone, Zhengzhou, Henan, China

MOB.: +86-15517518512

MOB.: +86-15515520695

E-MAIL: admin@dais.ltd

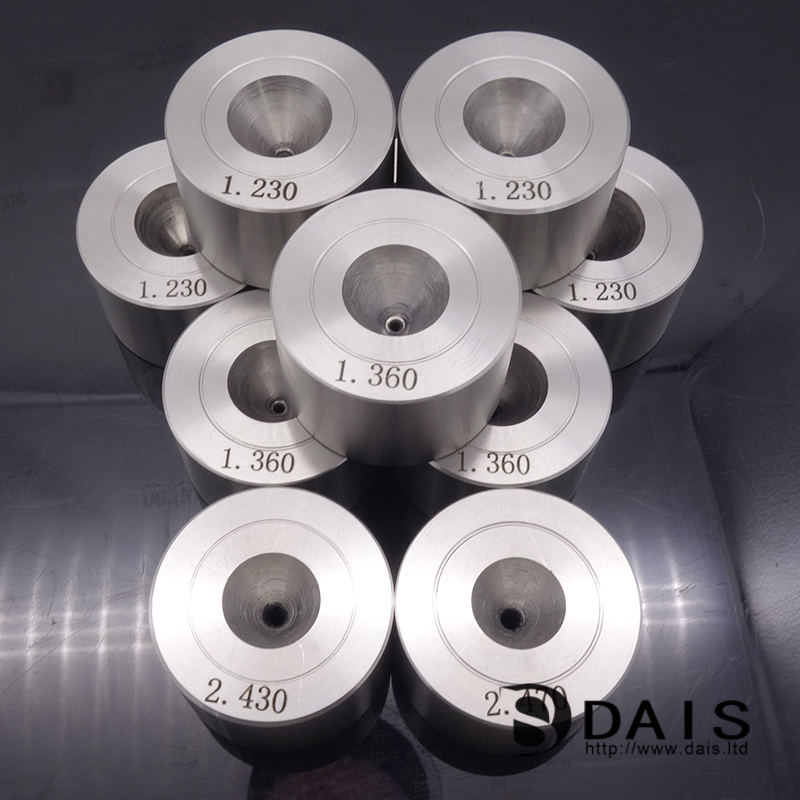

The materials of various drawing dies have their own characteristics. Among them, the natural diamond wire drawing die is the most expensive and extremely difficult to process. At the same time, due to the anisotropy of natural diamond, the hardness varies greatly in the radial range, and it is easy to produce severe wear in a certain direction, so natural diamond die It is used for processing wire with small diameter. The hardness of the cemented carbide mold is low, the wire drawn with the cemented carbide mold has high quality, and the surface roughness is low, but the wear resistance of the cemented carbide mold is poor, and the service life of the mold is short. The hardness of polycrystalline diamond molds is second only to natural diamonds. Because of its isotropic characteristics, it does not produce a single phenomenon of increased radial wear, but its price is high, the processing is difficult, and the manufacturing cost is high.

The CVD wire drawing die has good wear resistance due to the properties of diamond, and the surface roughness of the drawn wire is low, but the manufacturing process of the CVD wire drawing die is complicated, the processing is difficult, and the cost is high; High hardness and wear resistance, low production cost, is an excellent material for making wire drawing dies between diamond and cemented carbide. However, due to the poor toughness, poor thermal shock and difficult processing of ceramic materials, it has not been widely used for hot extrusion molding dies.

Comparison of advantages and disadvantages of several drawing die materials:

Drawing die material-advantages-disadvantages-scope of application

Alloy steel mold-easy to manufacture-poor wear resistance, short life-basically eliminated

Natural diamond-high hardness, good wear resistance-large brittleness, difficult to process-wire mold with a diameter of 1.2mm or less

Carbide-good polishing, low energy consumption-poor wear resistance, difficult processing-various diameter wire

Polycrystalline synthetic diamond-high hardness, good wear resistance-difficult processing, high cost-small wire, wire

CVD-high finish, good temperature resistance-complex process, difficult processing-small wire, wire

Ceramics-Wear resistance, high temperature resistance, good corrosion resistance-Thermal shock, poor toughness, difficult to process

In the drawing process of small wire and wire, natural diamond, polycrystalline diamond and CVD die are commonly used wire drawing die materials. When drawing small-diameter wires, CVD diamond dies overcome the anisotropy of natural diamond dies, while having excellent strength and hardness, the highest drawing output, and the surface quality also meets the requirements. The test proves that the life of the CVD diamond wire drawing die is equivalent to that of the natural diamond die, the product qualification rate is high, and the surface quality is better than the domestic polycrystalline diamond. Therefore, for the drawing of small-diameter wire, CVD diamond wire drawing die is an ideal choice.

Although wire drawing dies can be used to process various metals and alloy materials such as steel, copper, tungsten, molybdenum, etc., wire drawing dies of different materials have their own applicable processing scope, and the wear patterns and use of wire drawing dies of different materials when processing the same wire There is a big difference in life, so the reasonable selection of wire drawing die material is the key to ensuring successful application. Drawing dies of different materials have their relatively reasonable processing objects. The rationality of the drawing process mainly refers to the matching of the mechanical, physical and chemical properties of the drawing die and the wire to obtain the longest tool life. For example, when drawing copper wires of the same diameter, the service life of polycrystalline diamond dies is 300 to 500 times the life of hard metal dies, and when drawing nickel wires is only 80 to 100 times, when drawing molybdenum wires, The life span is only 50 to 80 times that of cemented carbide molds. When drawing carbon steel, the life of polycrystalline diamond molds is only 20 to 60 times that of cemented carbide molds. Due to the lack of systematic research on the matching theory of drawing dies and wires in China's wire and cable network, blind choices have been made and resources have been wasted. The friction and wear situation of the drawing die is very complicated, generally divided into two categories: damage and friction and wear.

The damage of wire drawing die can be divided into ring damage, tensile damage, and support surface damage. Friction and wear can be divided into abrasion wear, friction wear, corrosion wear, abrasion and wear caused by fine particles. The different working conditions (wire material, drawing die material, lubricant, etc.) make the drawing die wear and damage have its own unique process. The relationship between the wear and damage of the drawing die is interrelated in nature. The situation inside the drawing die may be very subtle, and some factors may work simultaneously, and their superposition effect is very complicated and difficult to understand. It is possible that the effect of one factor will obscure the effect of other factors. The above forms of damage and friction and wear may often be intertwined, which makes it more difficult to analyze the damage and wear mechanism of the drawing die. But in general, the order of wear resistance of drawing dies of various materials from high to low is: diamond drawing dies (without considering the anisotropy of natural diamond)-ceramic drawing dies-cemented carbide dies- The obsolete alloy steel mold.

Through the study of the material of the wire drawing die, the wire drawing die is developing towards high strength, high hardness, and high wear resistance. Various new materials that meet the requirements are emerging one after another. The wear resistance of the wire drawing die is greatly improved, and the wear and damage time is obvious. Delay, the life of the drawing die continues to increase, and the processing accuracy has also been improved to a certain extent. The scope of application of drawing processing is gradually expanding, from thick to thin wires of various specifications can be processed, and there are special-shaped molds for processing irregular wires.