Search

ADD:Building 123, Phase 3, Enterprise Base, No. 1 Lianhua Street, High-tech Industrial Development Zone, Zhengzhou, Henan, China

MOB.: +86-15517518512

MOB.: +86-15515520695

E-MAIL: admin@dais.ltd

in order to improve the life of the mold, the failed mold should be analyzed first. Before formulating technical solutions to improve mold life and adopting technical measures, it is necessary to understand the main failure modes of such molds, that is, to understand the most common and largest failure modes that lead to mold failures, their failure causes and main influencing factors. Since the same type of mold will also have different failure modes, for example, some molds may break and fail, while other molds may fail due to plastic deformation. It is necessary to grasp the proportion of various failure modes and each The service life of failed molds. For example, for certain types of molds, although some of the molds eventually fail due to wear, their service life is very high; and another part of the molds fails by fracture, and its life is extremely low. This requires a concentrated analysis of the causes of fracture and the first to solve the problem of fracture.

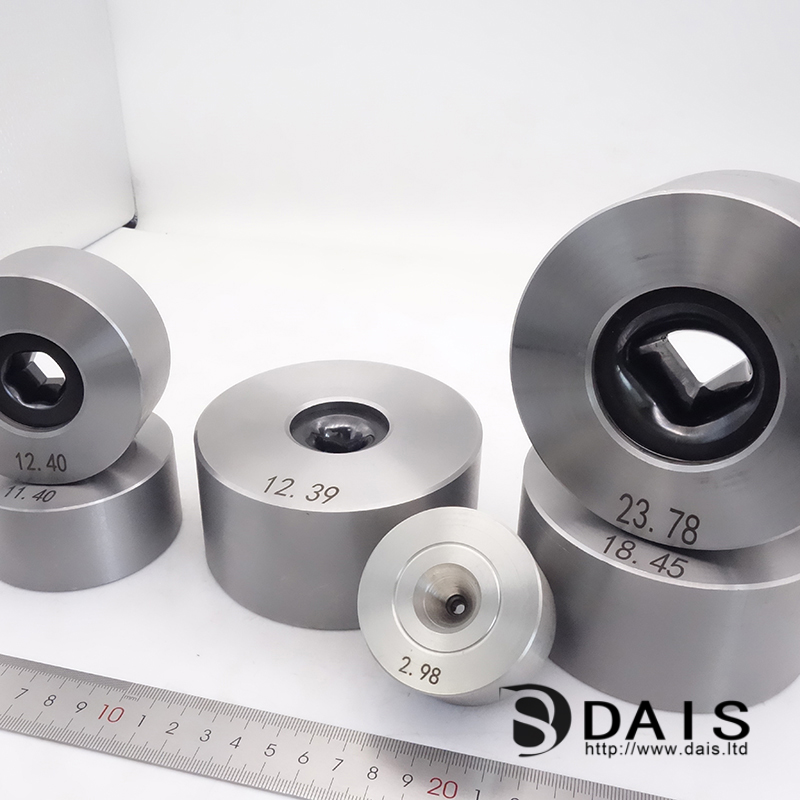

For different types of wire drawing dies, the main forms of failure will be different. For example, cold heading dies are prone to brittle failure, and hot work dies are prone to cold and heat fatigue failure. Even for the same type of mold, the form of failure varies.

The influence of mold material:

The diamond mold material must meet the mold's requirements for plastic deformation resistance, fracture resistance, fatigue resistance, hardness, wear resistance, cold and heat fatigue resistance, etc. If it cannot meet the requirements, early mold failure will occur. Under cyclic loading, if the fatigue resistance of the material is poor, after a constant stress cycle, fatigue cracks may develop and gradually expand until the die breaks and fails.

The metallurgical quality of die steel also has a great influence on the failure mode of the die. The strength and plasticity of non-metallic inclusions in steel are very low, and they are easy to form pattern source and cause early fracture failure of the mold. Excessive amount of carbides in the steel, unsatisfactory shape, size and distribution, severely reduce the impact toughness and fracture resistance of the steel, and cause chipping, breaking, and splitting of the mold. The center is loose and white spots, which reduce the compressive strength of steel, and it is easy to cause depression and quenching cracking on the working surface of the mold. Figure 1-3 (a) is a punch that failed due to thermal cracking, and Figure 1-3 (b) is a photo of the metallographic structure of the cut sample. It is found that the carbide bands are serious.