Search

ADD:Building 123, Phase 3, Enterprise Base, No. 1 Lianhua Street, High-tech Industrial Development Zone, Zhengzhou, Henan, China

MOB.: +86-15517518512

MOB.: +86-15515520695

E-MAIL: admin@dais.ltd

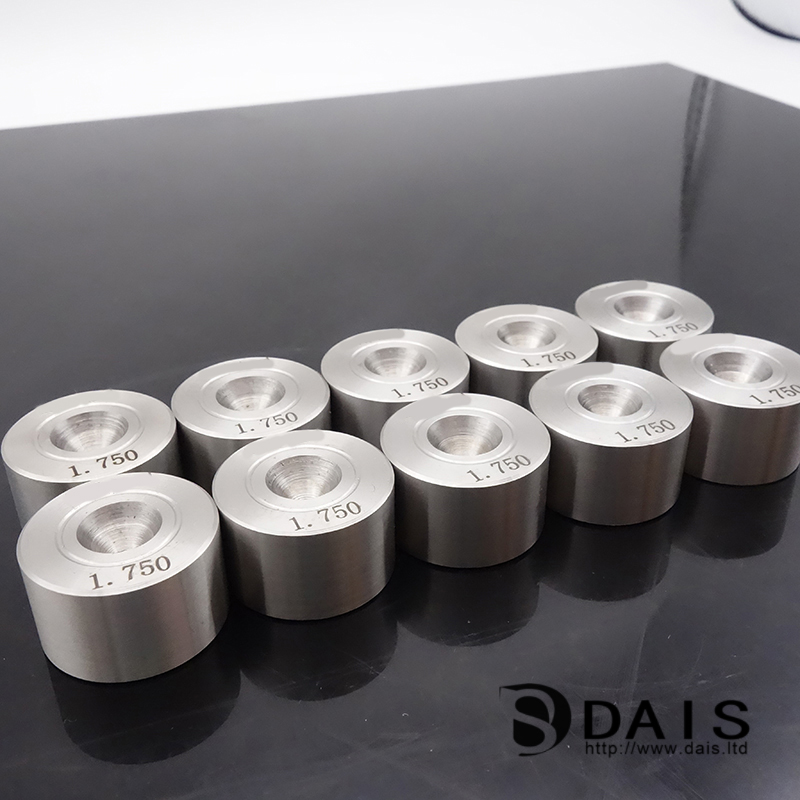

According to the nature of the work, the layout of the wire drawing die core can be divided into five sections: "import zone, smooth zone, work zone, sizing zone, and export zone". The inner diameter of the drawing die is very important. It determines the tension required to shrink the wire and affects the residual stress in the wire after drawing. The effects of each area of the mold core are: the entrance area, which facilitates threading and avoids the wire from scratching the drawing die from the entrance direction; the smooth area, through which the steel wire can be easily brought into the smoothing agent; the operating area is the most important part of the die hole, and the deformation of the wire The process takes place here to reduce the original cross-section to the required cross-sectional dimension. When drawing the conical metal, the space occupied by the volume of the metal in the work area is a truncated cone, which is called the deformation zone. The cone half angle α (also known as the die hole half angle) in the work area is mainly used to determine the size of the drawing force; the effect of the sizing area is to obtain the precise dimensions of the drawn steel wire; the exit area is used to avoid the unsteady exit of the steel wire And scratch the surface of the wire