Search

ADD:Building 123, Phase 3, Enterprise Base, No. 1 Lianhua Street, High-tech Industrial Development Zone, Zhengzhou, Henan, China

MOB.: +86-15517518512

MOB.: +86-15515520695

E-MAIL: admin@dais.ltd

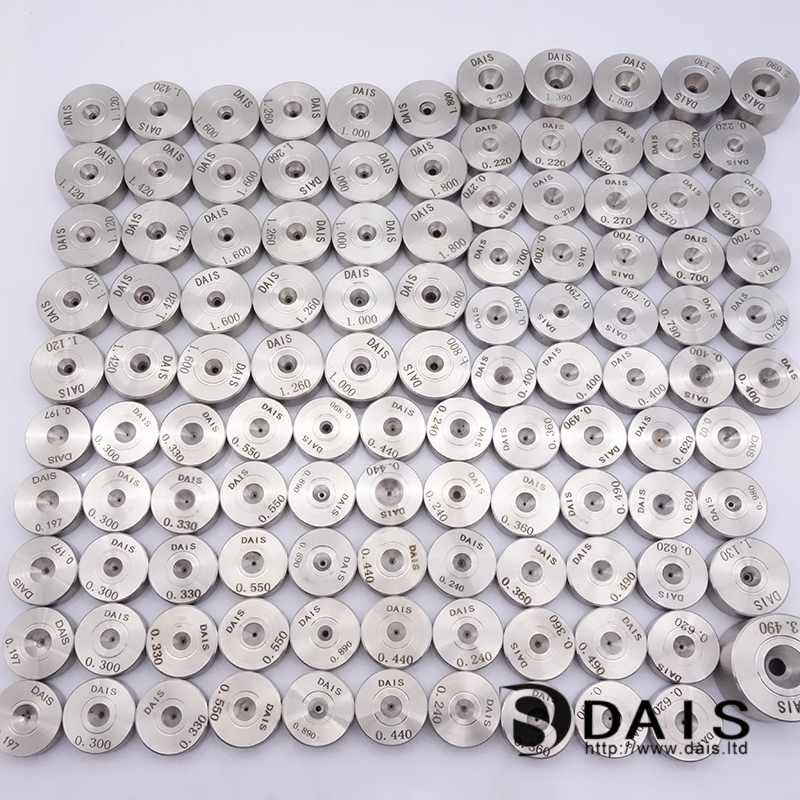

Performance comparison of polycrystalline wire drawing die and hard alloy wire drawing die

Compared with cemented carbide, the tensile strength of polycrystalline diamond is only 70% of common cemented carbide, but the hardness is 2.5 times that of cemented carbide. In this way, the polycrystalline diamond mold has more advantages than the cemented carbide mold. The wire drawing die made of polycrystalline diamond has good wear resistance, uniform inner hole wear, strong impact resistance and high wire drawing efficiency. Therefore, at present, polycrystalline diamond molds are gradually being valued in the metal wire drawing industry.

Drawing die comparison

Compared with cemented carbide molds, the use of polycrystalline diamond mold wire drawing molds has the following obvious advantages:

1. High drawing efficiency. The necessary maintenance of the drawing die during use is very important to the life of the drawing die and the surface quality of the wire. Generally, customers are advised to perform maintenance on the polycrystalline diamond drawing die every 24 hours. Within 24 hours, the diameter change of the polycrystalline diamond wire drawing die is small, and the change rate of the wire diameter of the drawn wire is also small. For the entire production process, the wire diameter compression rate of each drawing die is relatively stable, and the ratio of input and output is large.

2. Good abrasion resistance and long life. The life of polycrystalline diamond wire drawing die is about 30-50 times that of hard alloy die, so there is no need to frequently stop the machine to replace the die during the drawing process. The diameter of the polycrystalline wire drawing die changes little per unit time, and the size of the drawn wire changes little, which is very beneficial to the winding of the drum. Generally, the number of winding turns of the drawn wire is fixed. If the size of the finished wire product quickly increases, the number of winding turns decreases relatively quickly, which requires continuous change of the roll size, which is not conducive to the improvement of production efficiency.

3. Save raw materials. If the wire is coated with metal on the surface, the plating process does not stop during the drawing process. This will cause the thickness of the plating layer on the surface of the wire being plated to exceed the standard. Big waste, the more the downtime, the bigger the waste. The use of polycrystalline diamond molds can greatly reduce this waste.

4. Reduce labor intensity. Because polycrystalline diamond wire drawing die has a long life and slow number expansion, it is not necessary to change the mold frequently. It is also not necessary to pay attention to the change of wire size at all times like the carbide drawing die, which greatly reduces the labor intensity of a worker. A worker in the production process Zhongneng can take into account 4 to 5 wire drawing machines.