Search

ADD:Building 123, Phase 3, Enterprise Base, No. 1 Lianhua Street, High-tech Industrial Development Zone, Zhengzhou, Henan, China

MOB.: +86-15517518512

MOB.: +86-15515520695

E-MAIL: admin@dais.ltd

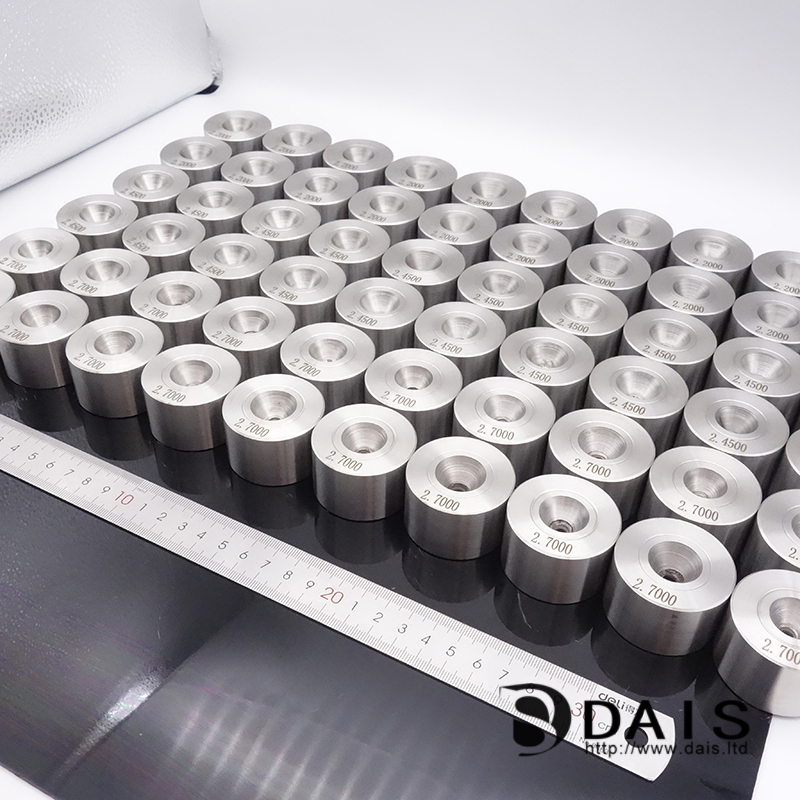

Selection method of drawing die material The correct selection of drawing die material, proper design of die hole shape and size, reasonable formulation of die structure and mold repair process, and accurate and precise drawing of drawing die are all of great significance for wire production.

1. Material of wire drawing die core:

Due to the constraints of the working conditions for wire drawing, the material of the drawing core must not only have high hardness and wear resistance, but also have sufficient strength (compressive strength and flexural strength), toughness and a very smooth working surface. At the same time, it must consider the factors of adapting to the corrosion of various lubricants, various coatings, and oxidation including the atmosphere, requiring low adhesion to the surface of the steel wire, small expansion coefficient and high thermal conductivity, and low cost and convenient processing. . At present, the wire production mainly uses drawing dies made of hard alloy.

Characteristics of cemented carbide materials:

Cemented carbide is an alloy made of refractory metal hard carbide as aggregate, cobalt as binder, powder metallurgy, mixing and pressure forming and sintering. The hard alloys currently applied are mainly divided into three categories: tungsten cobalt, tungsten cobalt titanium, and tungsten cobalt tantalum titanium, because the latter two types of alloys are relatively brittle and should not be used as wire drawing molds.

Tungsten-cobalt alloy wire drawing die The correct choice of wire drawing die material, the proper design of the shape and size of the die hole, the reasonable formulation of the die structure and the mold repair process, and the accurate and precise processing of the wire drawing die are all of great significance to the production of steel wires.

1.Characteristics of cemented carbide materials:

Cemented carbide is an alloy made of refractory metal hard carbide as aggregate, cobalt as binder, powder metallurgy, mixing and pressure forming and sintering. The hard alloys currently applied are mainly divided into three categories: tungsten cobalt, tungsten cobalt titanium, and tungsten cobalt tantalum titanium, because the latter two types of alloys are relatively brittle and should not be used as wire drawing molds.

2, the material of the drawing core:

Due to the constraints of the working conditions for wire drawing, the material of the drawing core must not only have high hardness and wear resistance, but also have sufficient strength (compressive strength and flexural strength), toughness and a very smooth working surface. At the same time, it must consider the factors of adapting to the corrosion of various lubricants, various coatings, and oxidation including the atmosphere, requiring low adhesion to the surface of the steel wire, small expansion coefficient and high thermal conductivity, and low cost and convenient processing. . At present, the wire production mainly uses drawing dies made of hard alloy.

(1) Strong polishing and low adhesion. The above mirror surface roughness can be processed, which can not only ensure the quality of wire surface drawing, but also because of its small friction coefficient, it can reduce the power consumption during drawing.

(2) High thermal conductivity, small linear expansion coefficient, thermal conductivity is only 0.14 ~ 0.21 cal / cm.degree.s., Which can better transfer heat during drawing.

(3) High hardness and good abrasion resistance. The hardness at room temperature is generally as high as HRA86 ~ 93, and it has the necessary red hardness. The hardness can be maintained below 500 ℃, and the hardness will be reduced above 500 ℃. Abrasion resistance is 15-20 times higher than high-speed tool steel (white steel force), which can ensure the accuracy of wire size under long-term drawing working conditions.

(4) Good corrosion resistance, the mold will not be oxidized and corroded during the use, storage, cleaning and grinding rework, and can work continuously for a long time.