Search

ADD:Building 123, Phase 3, Enterprise Base, No. 1 Lianhua Street, High-tech Industrial Development Zone, Zhengzhou, Henan, China

MOB.: +86-15517518512

MOB.: +86-15515520695

E-MAIL: admin@dais.ltd

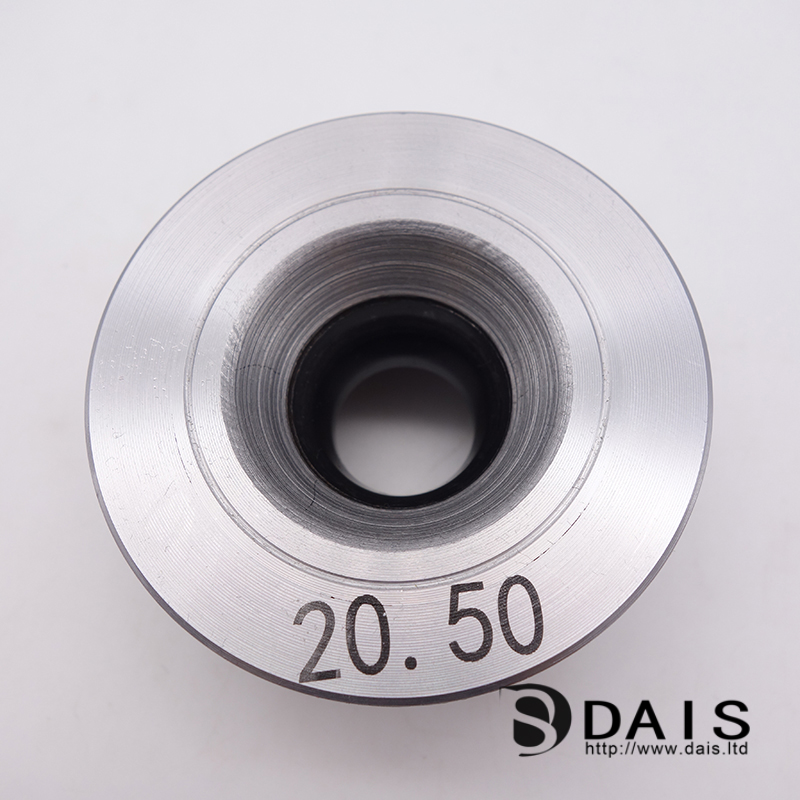

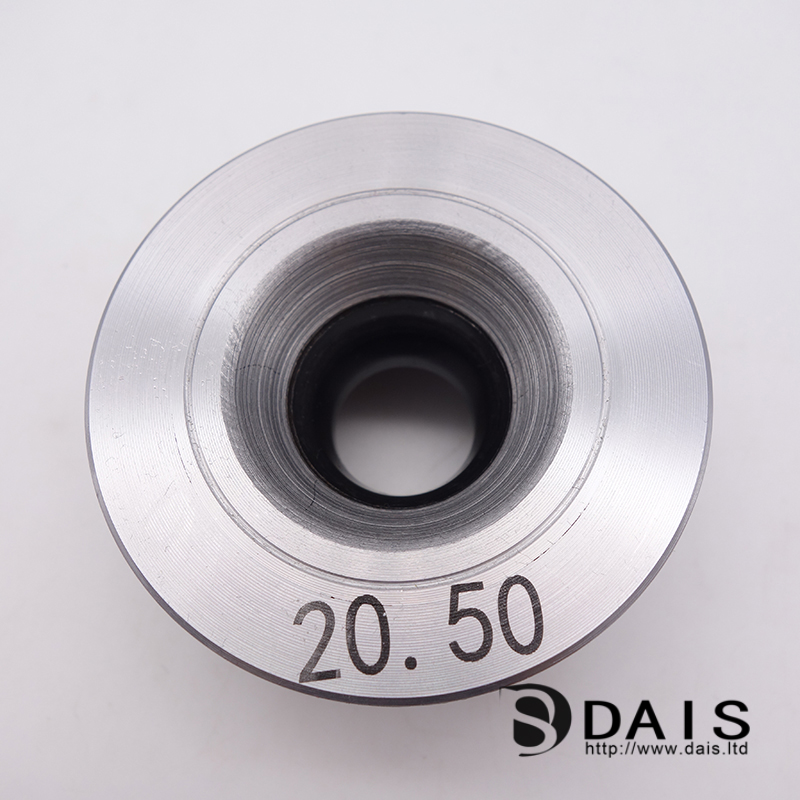

The conical surface is a compression zone for the wire (workpiece), and the cylinder is a sizing zone (polishing zone) of the wire drawing die, and the diameter of the wire is corresponding to the wire size of the Lj. The quality of the wire drawing directly affects the shape, the ruler, the J, the surface roughness and the service life of the wire. The drawing die grinding process adopted in China in the past is a needle grinding process introduced from the Soviet Union in the early 1950s. The IJ of this process is not highly reliable and the production efficiency is low.

The conical surface is a compression zone for the wire (workpiece), and the cylinder is a sizing zone (polishing zone) of the wire drawing die, and the diameter of the wire is corresponding to the wire size of the Lj. The quality of the wire drawing directly affects the shape, the ruler, the J, the surface roughness and the service life of the wire. The drawing die grinding process adopted in China in the past is a needle grinding process introduced from the Soviet Union in the early 1950s. The IJ of this process is not highly reliable and the production efficiency is low.

The reverse design of the wire drawing die polishing machine was developed to improve the service life of the wire drawing die, the polishing precision of the inner hole of the wire drawing die, and the polishing efficiency. The design of this subject will be a new type of wire drawing die polishing machine, which is mainly composed of two parts: the rotating mechanism of the clamp and the reciprocating mechanism of the wire frame. The machine is characterized in that the inner hole of the drawing die can be ground and polished at one time, so that the production efficiency is greatly improved. The reciprocating mechanism of the wire frame adopts counterweight balance, so that the wire frame is stable at high and low speeds, the processing range is widened, and the precision is improved, so that the processing of the small-diameter wire drawing die becomes a reality. The reverse design of the drawing die polishing machine has two main aspects: one is the design of the polishing wire reciprocating system, and the other is the fixture placement mechanism design.

Source and research of the topic

The country has become a global wire and cable product country. However, from the perspective of economic efficiency, the gap is very large. All kinds of crystals in the whole industry have basically survived in the quilted towel of Shangbuyou Enterprise, and have long been lingering on the edge of meager profit and loss. These must be of great concern to the umbrella industry. China's wire products industry is generally facing cost pressures. Its fundamental way out is to strengthen scientific and technological progress and technological innovation, increase the proportion of high value-added products, and further strengthen enterprise management, save resources and improve competitiveness.

It is estimated that in 2010, the consumption of domestic high-carbon wire products will increase to 8.65 million tons (excluding net exports). During the “Eleventh Five-Year Plan” period, the consumption of medium and high carbon wire products in China will continue to grow, but the growth rate will be reduced. Because the manufacturing cost of medium and high carbon wire (hard wire) Lj ordinary carbon steel wire has gradually narrowed the cost gap, which provides conditions for further development of high carbon wire products. In addition, with the reduction of the production cost of high-carbon wire products, especially the price of high-quality high-strength steel wire and products used in the construction industry, the gap between Lj ordinary low-carbon steel wire has gradually narrowed, creating conditions for the promotion of medium and high-carbon wire crystals in the construction industry. This will drive the continued growth of the total consumption of high-carbon products. The continuous development of the wire industry has put more and more demands on the wire drawing die. The low cost and high quality require the wire drawing die to have a longer service life and the inner hole precision to be higher. In short, the quality of the wire drawing die is to be improved.

The inner hole of the wire drawing die is composed of a cylindrical conical surface, the conical is a compression zone for the wire (work), the cylindrical surface is a sizing zone (polishing zone) of the wire drawing die, and the diameter of the wire is corresponding to the wire rod and J. The quality of the wire drawing die directly dialects the shape, size, surface roughness and service life of the material wire. The wire drawing die grinding process adopted in China in the past is a needle grinding process introduced from the Soviet Union in the early 1950s. Its working principle is that the mold rotates, and the needle-shaped grinding head makes micro-movement or swing in the grinding hole to reach the day of processing the die hole. The U-reliability of the process is not high, and the production efficiency is low. The needle-shaped grinding head is designed to be tapered in order to facilitate its penetration into the mold, and at the same time, a radial component is generated in the grinding process to improve the grinding effect. But it also brings a lot of drawbacks. First, the taper of the needle-shaped grinding head also has a taper for the die hole in which the rice is machined. When the taper hole is drawn by the taper, only the small end of the tapered die hole is used for the sizing. The sizing area is small, so the contact area during the polishing operation is small, and the periodic contact load or the alternating stress on the microscopic volume acts on the friction table during the working of the drawing die, and the table or sub-table is easily And a crack is formed. As a result, the mold L is severely worn and the quality of the wire polishing is poor. Secondly, the needle-shaped grinding head is made by work, and the shape of the grinding head is extremely difficult to present an ideal conical shape. Therefore, in the grinding process towel, since the needle grinding head is tapered, the radial component force exists, and almost no Sichuan can be completely balanced, and the resulting eccentric force causes the suspended grinding head to be

The deflection is now made to machine the eccentric die hole L. On the other hand, due to the irregularity of the die, high-frequency alternating stress occurs during the grinding process, so that vibration is generated. For a "cantilever beam" structure, the vibrations that exist during processing will have an impact on the life of the entire structure.